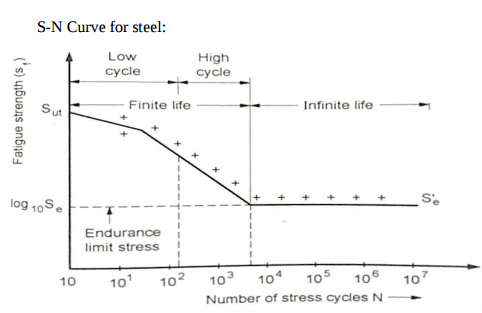

Define Endurance limit and draw typical S-N curve for steel.

Endurance Limit: It is defined as maximum value of the completely reversed bending stress which a polished standard specimen can withstand without failure, for infinite number of cycles (usually 107 cycles).It is known as endurance or fatigue limit (ϭe).