Hydraulics Pneumatic system applications

Q.1. State the applications of Hydraulic system. (4m)

Ans :

1)Industrial: Plastic processing machineries, steel making and primary metal extraction applications, automated production lines, machine tool industries, paper

industries, loaders, crushes, textile machineries, R & D equipment and robotic systems etc.

2)Mobile hydraulics: Tractors, irrigation system, earthmoving equipment, material handling equipment, commercial vehicles, tunnel boring equipment, rail

equipment,building and construction machineries and drilling rigs etc.

3)Automobiles: It is used in the systems like breaks, shock absorbers, steering system, wind shield, lift and cleaning etc.

4) Marine applications: It mostly

covers ocean going vessels, fishing boats and navel equipment.

5)Aerospace equipment : used in airplanes, rockets and spaceships

Q.2.Write any four applications of hydraulic systems (2m)

Ans : 1. Earth Moving equipments 2.Broaching machine 3. CNC/VMC/HMC Machines. 4.Hydraulic thread rolling machine 5. Hydraulic press brake.

6. Material handling equipments 7. Hydraulic thread rolling machine 8. Hydraulic cranes.

Q.3.Enlist Merits and demerits of Hydraulic system

Merits of Hydraulic system

1) We can generate very high pressures in hydraulic system. Due to this nature of hydraulic system we can use this power to lift, hold, press very heavy loads.

2) Weight to power ratio of a hydraulic system is comparatively less than that of an Electro-MechanicalSystem. Electric motor weigh appropriately 8.5 Kg/kW whereas, same power hydraulic motor weighs 0.85 kg/kW only. 3) The speed control of linear as well as rotary actuators can be achieved with ease. By merely adjusting small flow control valve, wide range of speed and feed can be obtained.

4) Limiting and balancing of hydraulic forces can be easily performed.

Demerits of hydraulic system

1) Elements of hydraulic system have to be machined to high degree of precision which increases manufacturing cost of system.

2) The hydraulic system, due to oil leakages is ‘dirty’ and we cannot use this system in food and pharmaceutical industry.

3) Petroleum based hydraulic oils can create fire hazards if the temperature of the system goes beyond its ‘flash point’

4) Leakage of hydraulic oil during its flow in system causes heavy pressure drops

Q.4. State the applications of Pneumatic system.

Ans :

1.Manufacturing industries, Automotive industry, machine tool manufacturers and domestic and commercial appliance manufacturers.

2.Processing industries, such as chemical, petrochemical, food processing, textiles, paper, etc.

3.Used in the brake system of automobiles, railway coaches, wagons and printing presses.

4.Application of Pneumatics systems is widely in industrial robots.

Q.5.Enlist Merits(Advantages) and demerits(Disadvantages) of Pneumatic system

Advantages of pneumatic system :

1.Easily available air - The working medium used by pneumatic system is easily and freely available everywhere.

2.Neat and clean system - Due to air being working medium the system is very neat and clean (as compared to oil in hydraulics) this advantage makes it highly applicable in food processing industries.

Where neatness and cleanliness is of prime importance.

3.Explosion proof characteristic of air – This characteristic of air makes the pneumatic system more applicable in hazardous area.

4.Air is easily transportable under pressure through common pipings.

5.Pneumatic elements are simpler and easier to operate. The pneumatic valves can be easily operated without applying much force.

6.Pneumatic system requires no reservoir, return line, complex filtering etc. hence, system is simple and light in weight.

7.Pneumatic systems are easier and quicker to maintain.

8.Pneumatic system has lower initial and operating costs.

Limitation of pneumatic system :

On the limitation side the major limitations are operating pressure and accuracy in motion of the

pneumatic system.

1) Pressure is limited: The pneumatic system can be used up-to maximum pressure of 8 to 10 bar, is very less as compared to 400 to 500 bar of hydraulic system

2) Accuracy of positioning: Due to the compressible nature of air, highly reliable and accurate motions can not be obtained, as that obtained by the hydraulic system.

3) Pressurized air storage :In pneumatics air should be compressed and kept under pressure at all times even there is no load on thesystem where as in hydraulics pressure is developed due to external

load.

Q.6.Compare hydraulic and pneumatic system.

Criteria |

Hydraulics |

Pneumatics |

Energy Carrier |

Oil |

Air |

Energy conversion From mech. |

Hydraulic pumps |

Air Compressors |

Energy transmission |

Pipes, hoses, tubes etc. |

Pipes hoses tubes, etc. |

Energy control |

Very good with various valves |

Very good with various valves |

Re- conversion of energy |

Hydraulic cylinder and motors |

Air Cylinders and Air motors |

Energy storage |

Limited with Accumulator |

High with air reservoir. |

Efficiency |

Low Due to losses in primary conversion, in valves and secondary conversions. |

Fair to good. |

Q.7. Compare oil and air as a medium in fluid system.

Ans :

1. When the system requirement is high speed, medium pressure (usually 6 to 8 bar) and less accuracy of position, then air system is preferred.

2. If the system requirement is high pressure and high precision, a fluid system with oil is good.

3. When the power requirement is high like in forging presses, sheet metal press, it is impossible to use air system. Oil hydraulics is the only choice . 4.Air is used where

quick response of actuator is required.

5. If temperate variation range in the system is large, then use of air system may run into condensation problems and oil is preferred.

6. Air is non-explosive, it is preferred where fire/electric hazard are expected. Oil systems are more prone to fire and electrical hazards and are not recommended in such

applications. Because air contains oxygen (about 20%) and is not sufficient alone to provide

7. Adequate lubrication of moving parts and seals, oil is usually introduced into the air stream near the actuator to provide this lubrication preventing excessive wear and oxidation. If the application requires only a medium pressure.

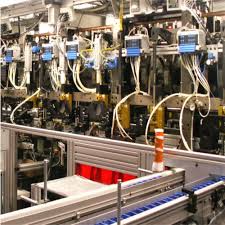

Hydraulics Pneumatic system applications in images

Following images depict various hydraulics pneumatic system in various fields.

- Log in to post comments